XML7M MCB Circuit Breaker Electro-Magnetic Protection

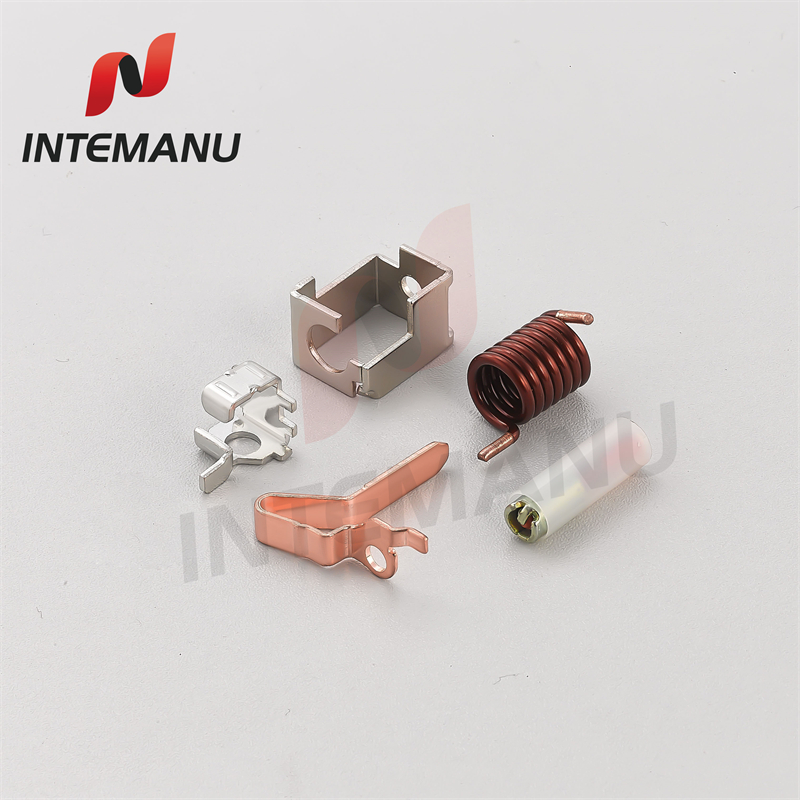

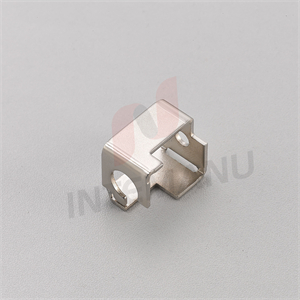

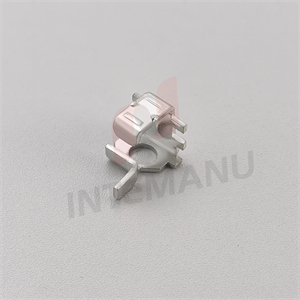

The XML7M MCB Circuit Breaker Electro-Magnetic Protection consists of coil, yoke, iron core, fix contact, and terminal.

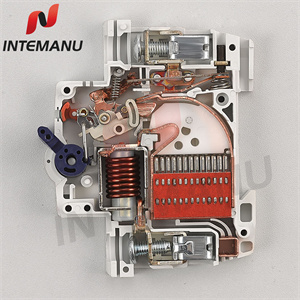

During short circuit condition, the current rises suddenly, causing electromechanical displacement of plunger associated with a tripping coil or solenoid. The plunger strikes the trip lever causing immediate release of latch mechanism consequently open the circuit breaker contacts. This was a simple explanation of a miniature circuit breaker working principle.

The most important thing that Circuit Breaker is doing is to safely and reliably switches off electrical circuit during abnormal conditions of the network, that means over load condition as well as faulty condition.