XMDPNM MCB Circuit Breaker Magnetic Trip Unit

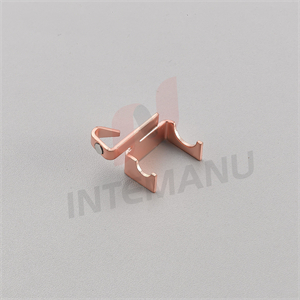

The XMDPN MCB Circuit Breaker Magnetic Trip Unit consists of coil, yoke with Static Contact, iron core, and terminal.

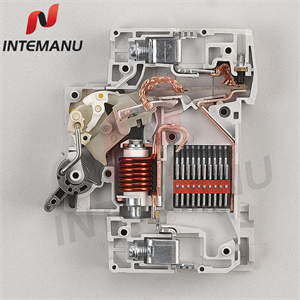

The operating mechanism consists of both magnetic tripping and thermal tripping arrangements.

The magnetic tripping arrangement essentially consists of a composite magnetic system that has a spring loaded dashpot with a magnetic slug in a silicon fluid, and a normal magnetic trip. A current carrying coil in the trip arrangement moves the slug against spring towards a fixed pole piece. So the magnetic pull is developed on the trip lever when there is a sufficient magnetic field produced by the coil.

In case of short circuits or heavy overloads, strong magnetic field produced by the coils (Solenoid) is sufficient to attract the armature of the trip lever irrespective of the position of the slug in the dashpot.