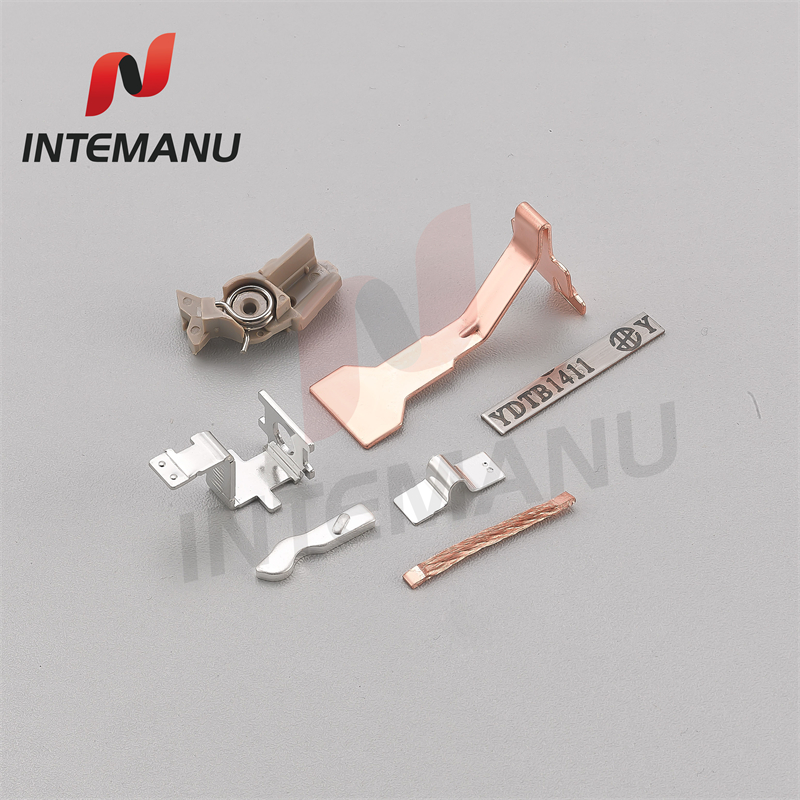

XMC65B MCB Circuit Breaker Thermal Tripping Mechanism

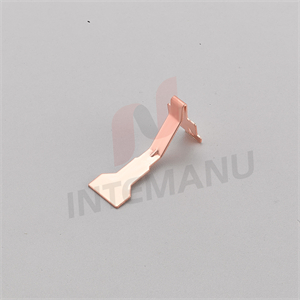

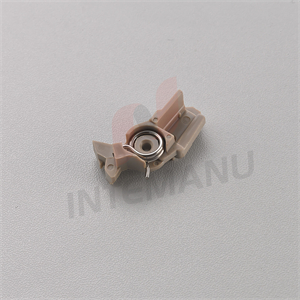

XMC65B MCB Circuit Breaker Thermal Tripping Mechanism consists of bimetall strip, soft connection, arc runner, braid wire, moving contact and moving contact holder.

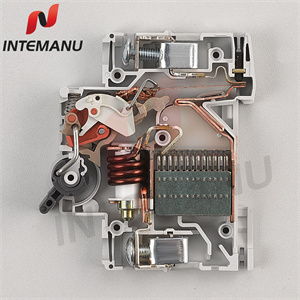

When the overflow of current takes place through MCB – Miniature Circuit Breaker, the bimetallic strip gets heated and it deflects by bending. The deflection of the bi-metallic strip releases a latch. The latch causes the MCB to turn off by stopping the flow of the current in the circuit.

Whenever continuous over current flows through MCB, the bimetallic strip is heated and deflects by bending. This deflection of bi-metallic strip releases a mechanical latch. As this mechanical latch is attached with the operating mechanism, it causes to open the miniature circuit breaker contacts, and the MCB turns off thereby stopping the current to flow in the circuit. To restart the flow of current the MCB must be manually turned ON. This mechanism protects from the faults arising due to over current or overload and short circuit.