Copper Wire Cable Manufacturer – XMWC1P Circuit Breaker Wire Component with Terminals – Ximu

Copper Wire Cable Manufacturer – XMWC1P Circuit Breaker Wire Component with Terminals – Ximu Detail:

Introduction

A residual-current device (RCD), is an electrical safety device that quickly breaks an electrical circuit with leakage current to ground. It is to protect equipment and to reduce the risk of serious harm from an ongoing electric shock.If the RCD device has additional overcurrent protection integrated in the same device, it is referred to as RCBO. An earth leakage circuit breaker may be a RCD, although an older type of voltage-operated earth leakage circuit breaker (ELCB) also exists.These electrical wiring devices are designed to quickly and automatically isolate a circuit when it detects that the electric current is unbalanced between the supply and return conductors of a circuit. Any difference between the currents in these conductors indicates leakage current, which presents a shock hazard. RCDs are designed to disconnect the conducting wires (“trip”) quickly enough to potentially prevent serious injury to humans, and to prevent damage to electrical devices.

Details

1.5mm2

2.5mm2

3mm2

4mm2

5mm2

6mm2

Our Advantages

1. Product Customization

Custom MCB parts or components are available upon request.

① How to customize the MCB parts or components?

Customer offers the sample or technical drawing, our engineer will make few samples for testing in 2 weeks. We will start making the mould after customer checks and confirms the sample.

② How long we take to make a new MCB parts or components?

We need 15 days to make sample for confirming. And making a new mould needs about 45 days.

2. Mature Technology

① We have technicians and toolmakers who can develop and design all kinds of MCB parts or components according to different requirements in the shortest time. All you need to do is to offer samples, profile or drawings.

② Most of the productions are automatic which can lower the cost.

3.Quality Control

We control the quality by many inspections. Firstly we have a incoming inspection for the raw material. And then process inspection for the rivet and stamping. Finally there is final statistical audit.

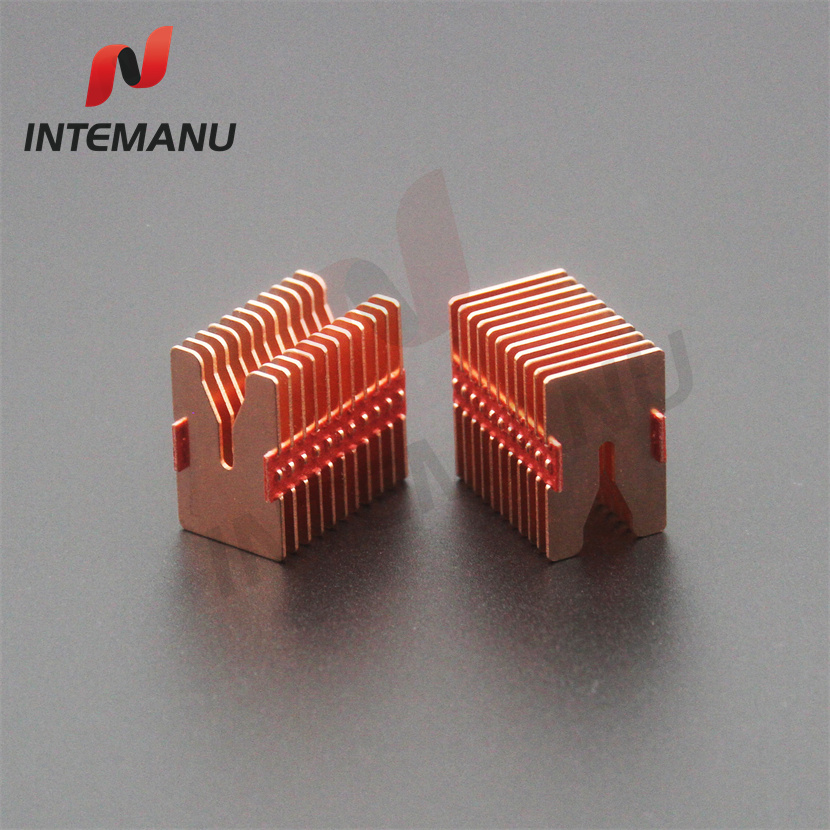

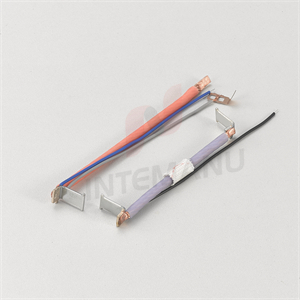

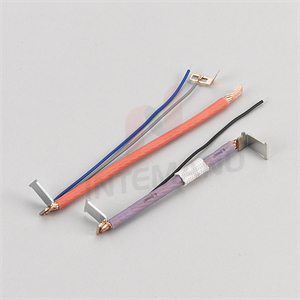

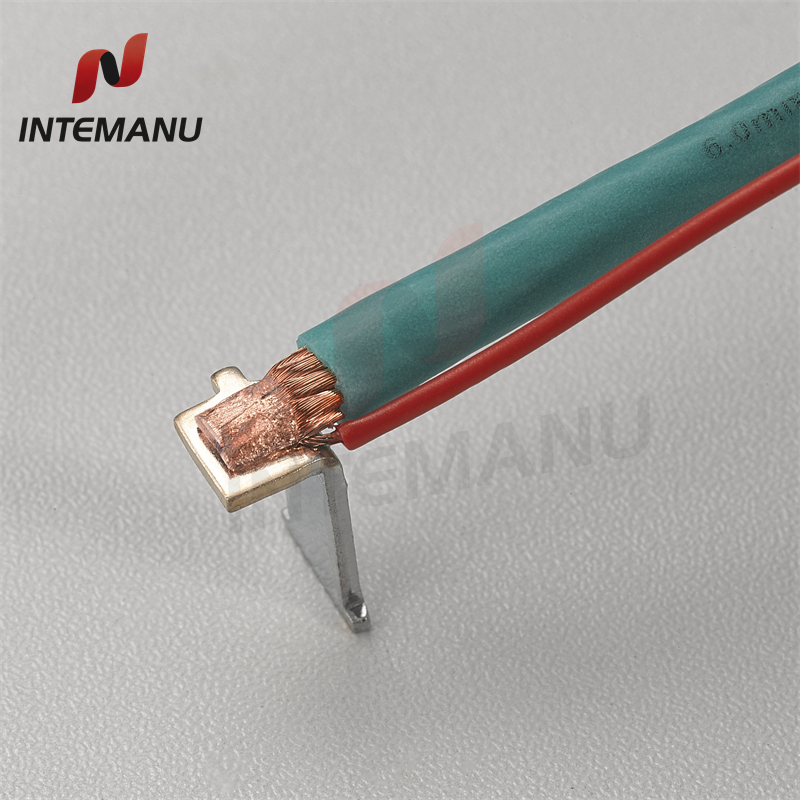

Product detail pictures:

Related Product Guide:

Cooperation

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for Copper Wire Cable Manufacturer – XMWC1P Circuit Breaker Wire Component with Terminals – Ximu, The product will supply to all over the world, such as: Singapore, Sevilla, Angola, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!