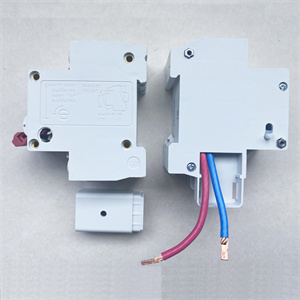

Copper Wire Bonding Factories – XMWC4P Circuit Breaker Wire Component with Terminals – Ximu

Copper Wire Bonding Factories – XMWC4P Circuit Breaker Wire Component with Terminals – Ximu Detail:

Introduction

RCDs are designed to disconnect the circuit if there is a leakage current.The most common modern application is as a safety device to detect small leakage currents and disconnecting quickly enough to prevent device damage or electrocution. They are an essential part of the automatic disconnection of supply.To prevent electrocution, RCDs should operate within 25–40 milliseconds with any leakage currents[clarification needed] (through a person) of greater than 30 mA, before electric shock can drive the heart into ventricular fibrillation, the most common cause of death through electric shock. By contrast, conventional circuit breakers or fuses only break the circuit when the total current is excessive (which may be thousands of times the leakage current an RCD responds to). A small leakage current, such as through a person, can be a very serious fault, but would probably not increase the total current enough for a fuse or overload circuit breaker to isolate the circuit, and not fast enough to save a life.

Details

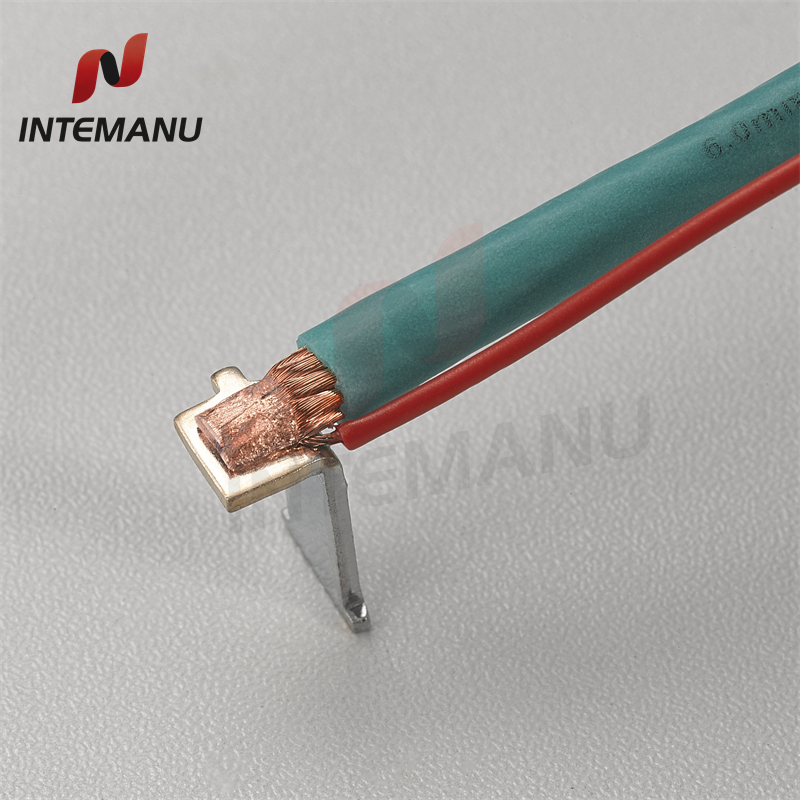

1.5mm2

3mm2

4mm2

5mm2

6mm2

Our Advantages

1. Product Customization

Custom MCB parts or components are available upon request.

① How to customize the MCB parts or components?

Customer offers the sample or technical drawing, our engineer will make few samples for testing in 2 weeks. We will start making the mould after customer checks and confirms the sample.

② How long we take to make a new MCB parts or components?

We need 15 days to make sample for confirming. And making a new mould needs about 45 days.

2. Mature Technology

① We have technicians and toolmakers who can develop and design all kinds of MCB parts or components according to different requirements in the shortest time. All you need to do is to offer samples, profile or drawings.

② Most of the productions are automatic which can lower the cost.

3.Quality Control

We control the quality by many inspections. Firstly we have a incoming inspection for the raw material. And then process inspection for the rivet and stamping. Finally there is final statistical audit.

Product detail pictures:

Related Product Guide:

Cooperation

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Copper Wire Bonding Factories – XMWC4P Circuit Breaker Wire Component with Terminals – Ximu, The product will supply to all over the world, such as: Israel, Puerto Rico, Bandung, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.