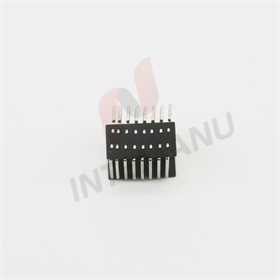

Arc chute for mcb XMCB3-125H with IRON 10#, PLASTIC PA66

The shape of arc extinguishing gate is mostly designed as V shape, which can reduce the resistance when the arc enters, and also optimize the magnetic circuit to enhance the suction force to the arc. The keys are the thickness of the grid when designing the arc chamber, as well as the distance between the grids and the number of grids. When the arc is driven into the arc chamber, the more grids it has the arc will be divided into the more short arcs, and the area cooled by the grids is larger, which is conducive to arc breaking. It is good to narrow the gap between the grids as far as possible (a narrow point can increase the number of short arcs, and also can make the arc close to the cold iron plate). At present, the thickness of most grids is between 1.5~2mm, and the material is cold rolled steel plate (10# steel or Q235A).