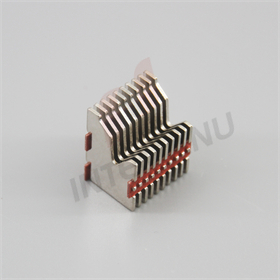

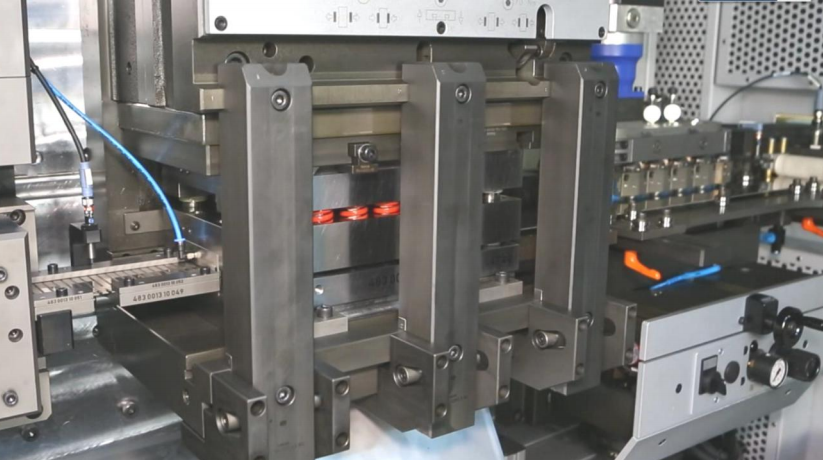

Arc chute for mcb XMCB2-40 10 grid pieces

There must be a certain tilt when rivet the grids, so that the gas exhausting will be better. It can also benefit in lengthening the short arc during the arc extinguishing.

The support of arc chamber grid is made of melamine glass cloth board, melamine formaldehyde plastic powder, red steel board and ceramics, etc. And vulcanized fiber board,polyester board, melamine board, porcelain (ceramics) and other materials are more used overseas. vulcanized fiber board is poor in heat resistance and quality, but the vulcanized fiber board will release a kind of gas under arc burning, which helps to extinguish the arc; Melamine board performs better, the cost is relatively high, and ceramics can not be processed, the price is also expensive.